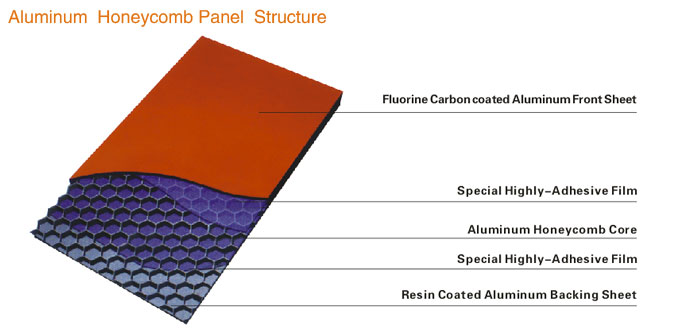

Honeycomb panels are mainly used for the decoration of exterior wall. Advanced Reynolux Roller Fluorocarbon Coating keeps the

panel colors from fading away for more than 30 years. Triple adopts two-fluid macromolecule epoxy and two-fluid modified epoxy

resin spraying in a totally enclosed dust-proof workshop. Full-Automatic honeycomb compositing equipment produces honeycomb

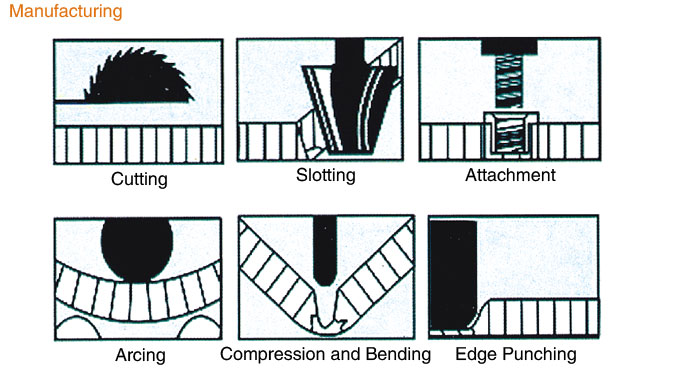

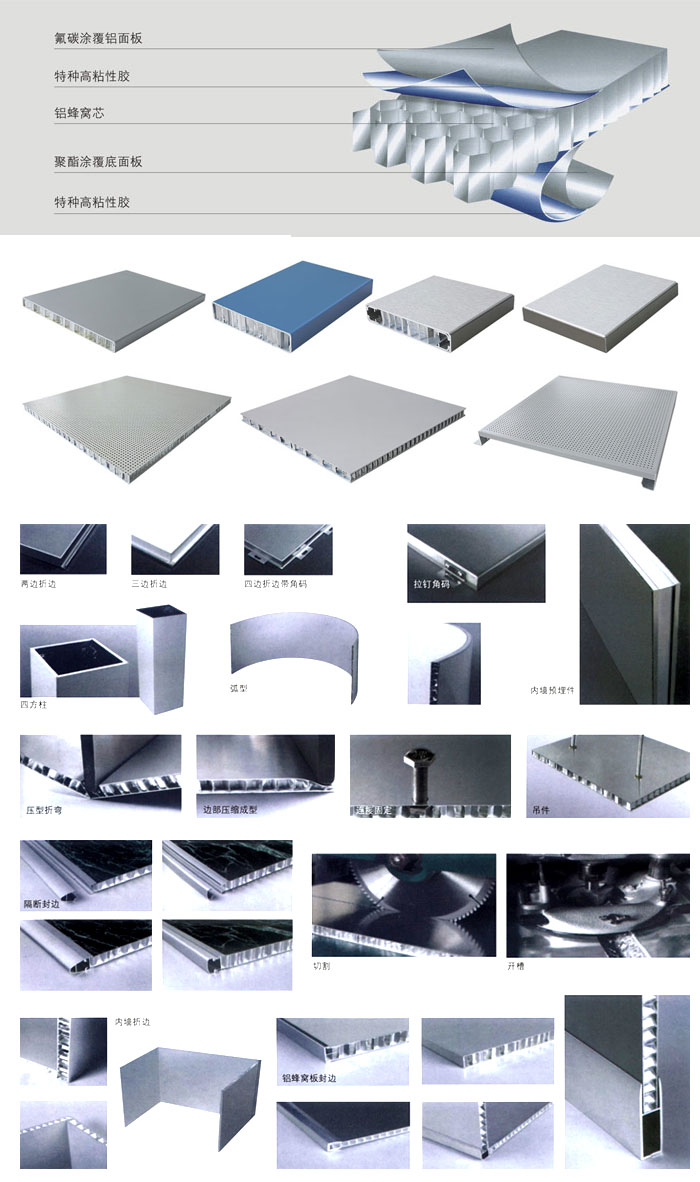

panels with the quality of great adherence, anti-bending. Curved, folded and trapeziform, L-shaped, U-shaped and any other

irregular honeycomb panels required by project design are fabricated by molding one-at-a- time. The same batch of roller coated

aluminum roll is adopted for one project to assure the color consistency. Epoxy fluorocarbon coating assures the corrosion

resistance of honeycomb panels. Salt mist spraying assures panels no pinholes, no flaws, no harmful gas and no bobbles

48 hours after coating.

Zero-radioactivity enables the material recyclable.